[ad_1]

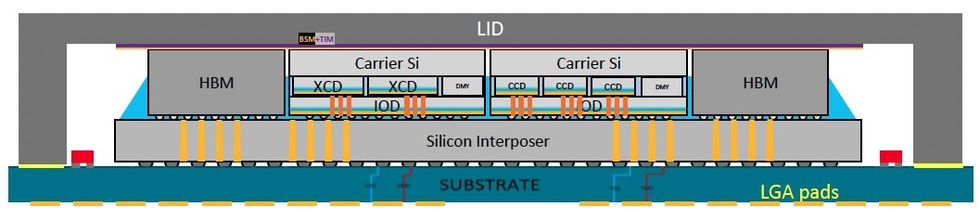

AMD lifted the hood on its subsequent AI accelerator chip, the Intuition MI300, on the AMD Advancing AI occasion right this moment, and it’s an unprecedented feat of 3D integration. MI300, a model of which can energy the El Capitan supercomputer, is a layer cake of computing, reminiscence, and communication that’s three slices of silicon excessive and that may sling as a lot as 17 terabytes of information vertically between these slices. The result’s as a lot as a 3.4-fold enhance in pace for sure machine-learning-critical calculations. The chip gives each contrasts and similarities to competing approaches akin to Nvidia’s Grace Hopper superchip and Intel’s supercomputer accelerator Ponte Vecchio.

MI300a stacks three CPU chiplets (known as compute advanced dies, or CCDs, in AMD’s lingo) and 6 accelerator chiplets (XCDs) on high of 4 input-output dies (IODs), all on high of a chunk of silicon that hyperlinks them collectively to eight stacks of high-bandwidth DRAM that ring the superchip. (The MI300x substitutes the CCDs for 2 extra XCDs, for an accelerator-only system.) With the scaling of transistors within the airplane of the silicon slowing down, 3D stacking is seen as a key methodology to get extra transistors into the identical space and maintain driving Moore’s Legislation ahead.

Compute and AI chiplets are stacked on high of I/O and cache chiplets within the MI300a.AMD

Compute and AI chiplets are stacked on high of I/O and cache chiplets within the MI300a.AMD

“It’s a really superb silicon stack up that delivers the best density efficiency that trade is aware of methods to produce at the moment,” says Sam Naffziger, a senior vice chairman and company fellow at AMD. The mixing is finished utilizing two Taiwan Semiconductor Manufacturing Co. applied sciences, SoIC (system on built-in chips) and CoWoS (chip on wafer on substrate). The latter stacks smaller chips on high of bigger ones utilizing hybrid bonding, which hyperlinks copper pads on every chip instantly with out solder. It’s used to supply AMD’s V-Cache, a cache-memory increasing chiplet that stacks on its highest-end CPU chiplets. The previous, CoWos, stacks chiplets on a bigger piece of silicon, known as an interposer, which is constructed to comprise high-density interconnects.

Similarities and variations between AMD and Nvidia

There are each similarities and variations to chief rival Nvidia’s method. Simply as Nvidia did in its Hopper structure, AMD’s accelerator structure, CDNA3, added the potential of computing with truncated 32-bit numbers known as TF32 and with two completely different types of 8-bit floating-point numbers. The latter attribute is used to hurry the coaching of sure components of transformer neural networks, akin to massive language fashions. In addition they each embody a scheme that reduces the scale of the neural community, known as 4:2 sparsity.

One other similarity is the inclusion of each CPU and GPU in the identical bundle. In lots of AI laptop methods, GPUs and CPUs are individually packaged chips deployed in a 4 to 1 ratio. One benefit to becoming a member of them collectively in a single superchip is that each CPU and GPU have high-bandwidth entry to the identical cache and high-bandwidth DRAM (HBM) in a approach that received’t journey one another up as they learn and write knowledge.

Nvidia’s Grace Hopper is such a superchip mixture linking the Grace CPU to the Hopper GPU by Nvidia’s Nvidia NVLink Chip-2-Chip interconnects. AMD’s MI300a is as effectively, by integrating three CPU dies designed for its Genoa line and 6 XCD accelerators utilizing its AMD Infinity Material interconnect know-how.

However an off-the-cuff look at Grace Hopper and MI300 present some profound variations. Grace and Hopper are every particular person dies that combine all of a system-on-chip’s wanted purposeful blocks—compute, I/O, and cache. They’re linked horizontally, and they’re massive—practically on the dimension restrict of photolithography know-how.

AMD took a special method, one which it has adopted for a number of generations of its CPUs and that rival Intel used for its 3D-stacked supercomputer accelerator Ponte Vecchio. The idea known as system-technology-co-optimization, or STCO. Which means designers began by breaking the chip down into its capabilities and determined which capabilities wanted which manufacturing know-how.

![]() A slice of MI300 stack from the provider silicon on the high to the solder ball on the backside of the bundle.AMD

A slice of MI300 stack from the provider silicon on the high to the solder ball on the backside of the bundle.AMD

“What we wished to do with MI300 was to scale past what was doable in a single monolithic GPU. So we deconstructed it into items after which constructed it again up,” says Alan Smith, a senior fellow and the chief architect for Intuition. Though it’s been doing so for a number of generations of CPUs, the MI300 is the primary time the corporate has made GPU chiplets and sure them in a single system.

“Breaking the GPU into chiplets allowed us to place the compute in essentially the most superior course of node whereas maintaining the remainder of the chip in know-how that’s extra applicable for cache and I/O,” he says. Within the case of the MI300, all of the compute was constructed utilizing TSMC’s N5 course of, essentially the most superior obtainable and the one used for Nvidia’s top-line GPUs. Neither the I/O capabilities nor the system’s cache reminiscence profit from N5, so AMD selected a less-expensive know-how (N6) for these. Subsequently, these two capabilities may then be constructed collectively on the identical chiplet.

With the capabilities damaged up, all of the items of silicon concerned within the MI300 are small. The biggest, the I/O dies, usually are not even half the scale of Hopper. And the CCDs are solely about one-fifth the scale of the I/O die. The small sizes make an enormous distinction. Typically, smaller chips yield higher. That’s, a single wafer will present a better proportion of working small chips than it could massive chips. “3D integration isn’t free,” says Naffziger. However the greater yield offsets the price, he says.

Luck and expertise

The design concerned some intelligent reuse of current applied sciences and designs, just a few compromises, and just a little luck, in accordance with Naffziger, an IEEE Fellow. The reuse got here in two cases. First, AMD was capable of do the 3D integration with a level of confidence as a result of it had already been utilizing the very same pitch of vertical interconnects—9 micrometers—in its V-cache product.

As an non-obligatory add-on that AMD was capable of cost further for, V-cache gives little threat that poor yield or different issues can have a huge impact on the corporate. “It’s been an important factor to allow us to wring out the manufacturing issues and all of the design complexities of 3D stacking with out endangering the principle product line,” says Naffziger.

The opposite occasion of reuse was a bit chancier. When the MI300 staff determined {that a} CPU/GPU mixture was wanted, Naffziger “considerably sheepishly” requested the pinnacle of the staff designing the Zen4 CCD for the Genoa CPU if the CCD could possibly be made to suit the MI300’s wants. That staff was underneath stress to satisfy an earlier deadline than anticipated, however a day later they responded. Naffziger was in luck; the Zen4 CCD had a small clean house in simply the fitting spot to make the vertical connections to the MI300 I/O die and their related circuitry with out a disruption to the general design.

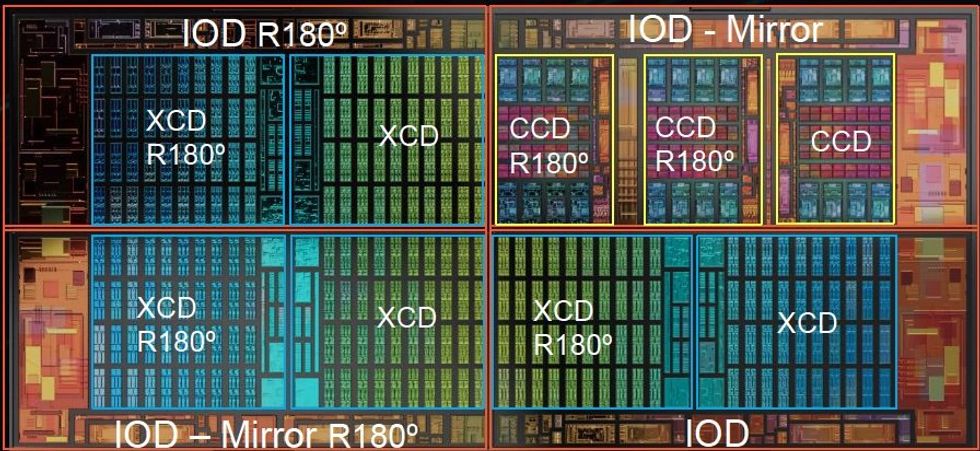

However, there was nonetheless some geometry that wanted fixing. To make all the interior communications work, the 4 I/O chiplets needed to be dealing with one another on a selected edge. That meant making a mirror-image model of the chiplet. As a result of it was codesigned with the I/O chiplet, the XCD and its vertical connections have been constructed to hyperlink up with each variations of the I/O. However there was no messing with the CCD, which they have been fortunate to have in any respect. So as an alternative the I/O was designed with redundant connections, in order that irrespective of which model of the chiplet it sat on, the CCD would join.

To get every part to line up, the IOD chiplets needed to be made as mirrors of one another, and the accelerator (XCD) and compute (CCD) chiplets needed to be rotated.AMD

To get every part to line up, the IOD chiplets needed to be made as mirrors of one another, and the accelerator (XCD) and compute (CCD) chiplets needed to be rotated.AMD

The ability grid, which has to ship a whole bunch of amperes of present to the compute dies on the high of the stack, confronted related challenges as a result of it too needed to accommodate all the varied chiplet orientations, Naffziger famous.

From Your Website Articles

Associated Articles Across the Net

[ad_2]