A startling change in medical ultrasound is working its approach by way of hospitals and physicians’ places of work. The long-standing, state-of-the-art ultrasound machine that’s pushed round on a cart, with cables and a number of probes dangling, is being wheeled apart completely in favor of handheld probes that ship photos to a telephone.

These units are sufficiently small to slot in a lab coat pocket and versatile sufficient to picture any a part of the physique, from deep organs to shallow veins, with sweeping 3D views, all with a single probe. And the AI that accompanies them might quickly make these units operable by untrained professionals in any setting—not simply skilled sonographers in clinics.

The primary such miniaturized, handheld ultrasound probe arrived in the marketplace in 2018, from

Butterfly Community in Burlington, Mass. Final September, Exo Imaging in Santa Clara, Calif., launched a competing model.

Making this attainable is silicon ultrasound know-how, constructed utilizing a kind of microelectromechanical system (MEMS) that crams 4,000 to 9,000 transducers—the units that convert electrical alerts into sound waves and again once more—onto a 2-by-3-centimeter silicon chip. By integrating MEMS transducer know-how with subtle electronics on a single chip, these scanners not solely replicate the standard of conventional imaging and 3D measurements but in addition open up new functions that had been not possible earlier than.

How does ultrasound work?

To know how researchers achieved this feat, it’s useful to know the fundamentals of ultrasound know-how. Ultrasound probes use transducers to transform electrical vitality to sound waves that penetrate the physique. The sound waves bounce off the physique’s gentle tissue and echo again to the probe. The transducer then converts the echoed sound waves to electrical alerts, and a pc interprets the info into a picture that may be seen on a display.

Standard ultrasound probes include transducer arrays constructed from slabs of piezoelectric crystals or ceramics equivalent to lead zirconium titanate (PZT). When hit with pulses of electrical energy, these slabs broaden and contract and generate high-frequency ultrasound waves that bounce round inside them.

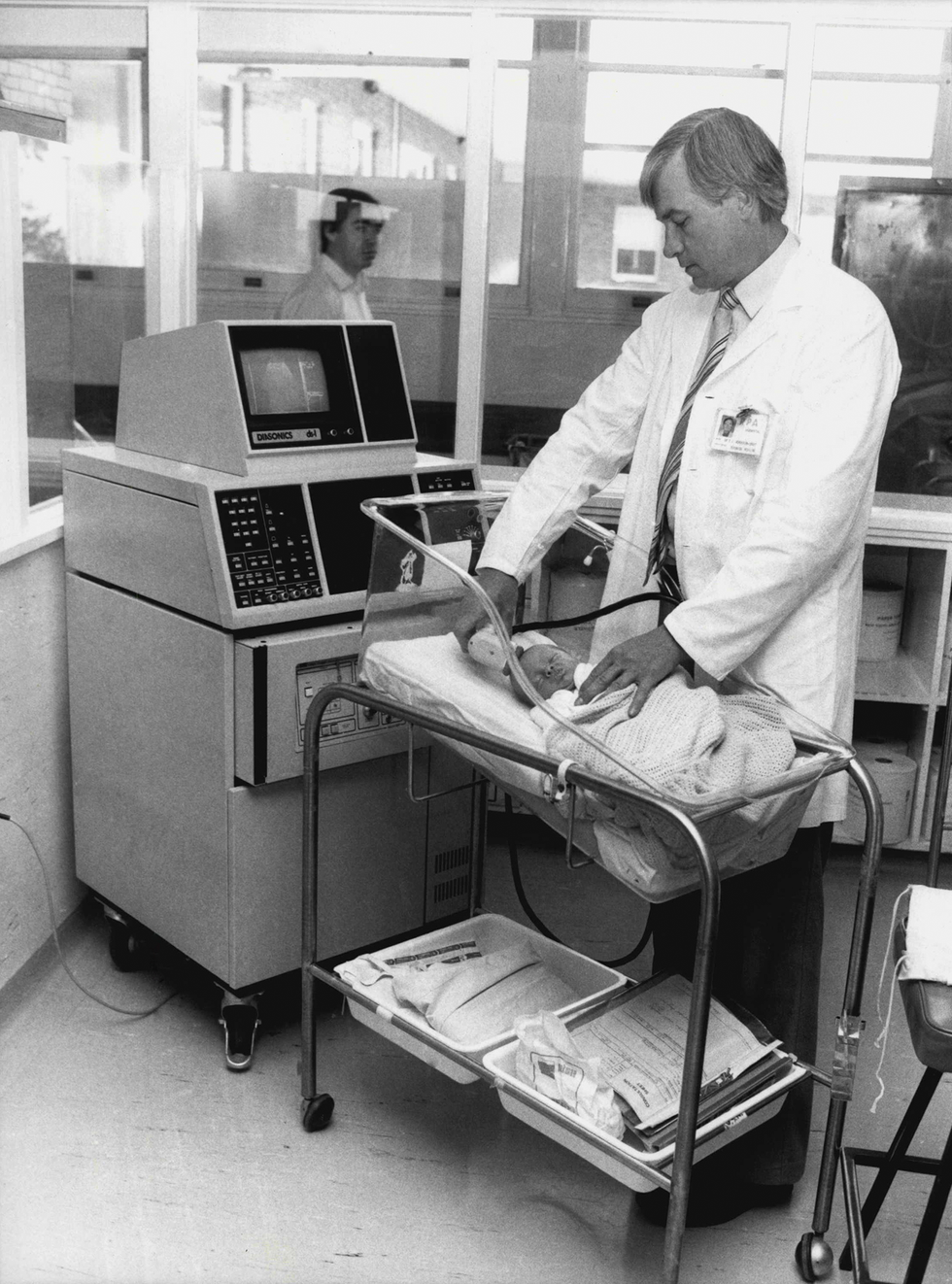

Ultrasound know-how has traditionally required cumbersome equipment with a number of probes. Julian Kevin Zakaras/Fairfax Media/Getty Photos

Ultrasound know-how has traditionally required cumbersome equipment with a number of probes. Julian Kevin Zakaras/Fairfax Media/Getty Photos

To be helpful for imaging, the ultrasound waves must journey out of the slabs and into the gentle tissue and fluid of the affected person’s physique. This isn’t a trivial activity. Capturing the echo of these waves is like standing subsequent to a swimming pool and attempting to listen to somebody talking underneath the water. The transducer arrays are thus constructed from layers of fabric that easily transition in stiffness from the laborious piezoelectric crystal on the middle of the probe to the gentle tissue of the physique.

The frequency of vitality transferred into the physique is set primarily by the thickness of the piezoelectric layer. A thinner layer transfers larger frequencies, which permit smaller, higher-resolution options to be seen in an ultrasound picture, however solely at shallow depths. The decrease frequencies of thicker piezoelectric materials journey additional into the physique however ship decrease resolutions.

In consequence, a number of forms of ultrasound probes are wanted to picture varied elements of the physique, with frequencies that vary from 1 to 10 megahertz. To picture massive organs deep within the physique or a child within the womb, physicians use a 1- to 2-MHz probe, which might present 2- to 3-millimeter decision and may attain as much as 30 cm into the physique. To picture blood circulate in arteries within the neck, physicians sometimes use an 8- to 10-MHz probe.

How MEMS remodeled ultrasound

The necessity for a number of probes together with the shortage of miniaturization meant that standard medical ultrasound methods resided in a heavy, boxy machine lugged round on a cart. The introduction of MEMS know-how modified that.

Over the past three many years MEMS has allowed producers in an

array of industries to create exact, extraordinarily delicate elements at a microscopic scale. This advance has enabled the fabrication of high-density transducer arrays that may produce frequencies within the full 1- to 10-MHz vary, permitting imaging of a variety of depths within the physique, all with one probe. MEMS know-how additionally helped miniaturize further elements in order that the whole lot matches within the handheld probe. When coupled with the computing energy of a smartphone, this eradicated the necessity for a cumbersome cart.

The primary MEMS-based silicon ultrasound prototypes emerged within the mid-Nineties when the thrill of MEMS as a brand new know-how was peaking. The important thing ingredient of those early transducers was the vibrating micromachined membrane, which allowed the units to generate vibrations in a lot the identical approach that banging on a drum creates sound waves within the air.

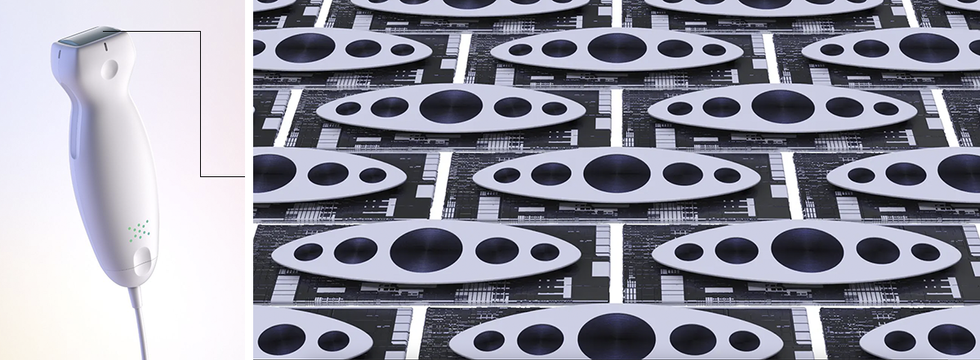

Exo Imaging developed a handheld ultrasound machine utilizing piezoelectric micromachined ultrasonic transducer (PMUT) know-how.Exo Imaging

Exo Imaging developed a handheld ultrasound machine utilizing piezoelectric micromachined ultrasonic transducer (PMUT) know-how.Exo Imaging

Two architectures emerged. One in every of them, known as the

capacitive micromachined ultrasonics transducer, or CMUT, is known as for its easy capacitor-like buildings. Stanford College electrical engineer Pierre Khuri-Yakub and colleagues demonstrated the primary variations.

The CMUT is predicated on electrostatic forces in a capacitor shaped by two conductive plates separated by a small hole. One plate—the micromachined membrane talked about earlier than—is product of silicon or asilicon nitride with a steel electrode. The opposite—sometimes a micromachined silicon wafer substrate—is thicker and extra inflexible. When a voltage is utilized, putting reverse prices on the membrane and substrate, engaging forces pull and flex the membrane towards the substrate. When an oscillating voltage is added, that modifications the power, inflicting the membrane to vibrate, like a struck drumhead.

When the membrane is in touch with the human physique, the vibrations ship ultrasound frequency waves into the tissue. How a lot ultrasound is generated or detected will depend on the hole between the membrane and the substrate, which must measure at about one micrometer or much less. Micromachining methods made that type of precision attainable.

The opposite MEMS-based structure is named the

piezoelectric micromachined ultrasonic transducer, or PMUT, and it really works like a miniaturized model of a smoke alarm buzzer. These buzzers encompass two layers: a skinny steel disk mounted round its periphery and a skinny, smaller piezoelectric disk bonded on prime of the steel disk. When voltages are utilized to the piezoelectric materials, it expands and contracts in thickness and back and forth. As a result of the lateral dimension is far bigger, the piezo disk diameter modifications extra considerably and within the course of bends the entire construction. In smoke alarms, these buildings are sometimes 4 cm in diameter, they usually’re what generates the shrieking sound of the alarm, at round 3 kilohertz. When the membrane is scaled all the way down to 100 μm in diameter and 5 to 10 μm in thickness, the vibration strikes up into megahertz frequencies, making it helpful for medical ultrasound.

Honeywell within the early Nineteen Eighties developed the primary micromachined sensors utilizing piezoelectric skinny movies constructed on silicon diaphragms. The primary PMUTs working at ultrasound frequencies didn’t emerge till

1996, from the work of supplies scientist Paul Muralt on the Swiss Federal Institute of Know-how Lausanne (EPFL), in Switzerland.

Early years of CMUT

An enormous problem with CMUTs was getting them to generate sufficient stress to ship sound waves deep into the physique and obtain the echoes coming again. The membrane’s movement was restricted by the exceedingly small hole between the membrane and the substrate. This constrained the amplitude of the sound waves that might be generated. Combining arrays of CMUT units with totally different dimensions right into a single probe to extend the frequency vary additionally compromised the stress output as a result of it decreased the probe space out there for every frequency.

Butterfly Community developed a handheld ultrasound machine utilizing capacitive micromachined ultrasonic transducer (CMUT) know-how.Butterfly

Butterfly Community developed a handheld ultrasound machine utilizing capacitive micromachined ultrasonic transducer (CMUT) know-how.Butterfly

The answer to those issues got here from Khuri-Yakub’s lab at Stanford College. In

experiments within the early 2000s, the researchers discovered that growing the voltage on CMUT-like buildings precipitated the electrostatic forces to beat the restoring forces of the membrane. In consequence, the middle of the membrane collapses onto the substrate.

A collapsed membrane appeared disastrous at first however turned out to be a approach of creating CMUTs each extra environment friendly and extra tunable to totally different frequencies. The effectivity elevated as a result of the hole across the contact area was very small, growing the electrical area there. And the stress elevated as a result of the massive doughnut-shaped area across the edge nonetheless had a superb vary of movement. What’s extra, the frequency of the machine might be adjusted just by altering the voltage. This, in flip, allowed a single CMUT ultrasound probe to supply all the ultrasound frequency vary wanted for medical diagnostics with excessive effectivity.

Inside Butterfly Community’s CMUT ultrasound probe, the membrane collapses onto the substrate, producing an acoustic wave.Butterfly Community

From there, it took greater than a decade to grasp and mannequin the sophisticated electromechanical habits of CMUT arrays and iron out the manufacturing. Modeling these units was difficult as a result of hundreds of particular person membranes interacted in every CMUT array.

On the manufacturing aspect, the challenges concerned discovering the appropriate supplies and growing the processes wanted to supply clean surfaces and a constant hole thickness. For instance, the skinny dielectric layer that separates the conductive membrane and the substrate should face up to about 100 volts at a thickness of 1 μm. If the layer has defects, prices will be injected into it, and the machine can brief on the edges or when the membrane touches the substrate, killing the machine or at the very least degrading its efficiency.

Ultimately, although, MEMS foundries equivalent to Philips Engineering Options in Eindhoven, Netherlands, and Taiwan Semiconductor Manufacturing Co. (TSMC), in Hsinchu, developed options to those issues. Round 2010, these firms started producing dependable, high-performance CMUTs.

Early growth of PMUTs

Early PMUT designs additionally had bother producing sufficient stress to work for medical ultrasound. However they may bang out sufficient to be helpful in some client functions, equivalent to

gesture detection and proximity sensors. In such “in-air ultrasound” makes use of, bandwidth isn’t essential, and frequencies will be under 1 MHz.

In 2015, PMUTs for medical functions acquired an sudden enhance with the introduction of enormous 2D matrix arrays for fingerprint sensing in cell phones. Within the first demonstration of this method, researchers on the College of California, Berkeley, and the College of California, Davis, related round 2,500 PMUT parts to CMOS electronics and positioned them underneath a silicone rubberlike layer. When a fingertip was pressed to the floor, the prototype measured the amplitudes of the mirrored alerts at 20 MHz to differentiate the ridges within the fingertip from the air pockets between them.

This was a powerful demonstration of integrating PMUTs and electronics on a silicon chip, and it confirmed that giant 2D PMUT arrays may produce a excessive sufficient frequency to be helpful for imaging of shallow options. However to make the soar to medical ultrasound, PMUT know-how wanted extra bandwidth, extra output stress, and piezoelectric skinny movies with higher effectivity.

Assist got here from semiconductor firms equivalent to

ST Microelectronics, based mostly in Geneva, which found out the right way to combine PZT skinny movies on silicon membranes. These movies require additional processing steps to keep up their properties. However the enchancment in efficiency made the price of the additional steps worthwhile.

To realize a bigger stress output, the piezoelectric layer wanted to be thick sufficient to permit the movie to maintain the excessive voltages required for good ultrasound photos. However elevated thickness results in a extra inflexible membrane, which reduces the bandwidth.

One resolution was to make use of an oval-shaped PMUT membrane that successfully mixed a number of membranes of various sizes into one. That is just like altering the size of guitar strings to generate totally different tones. The oval membrane supplies strings of a number of lengths on the identical construction with its slim and broad sections. To effectively vibrate wider and narrower elements of the membrane at totally different frequencies, electrical alerts are utilized to a number of electrodes positioned on corresponding areas of the membrane. This method allowed PMUTs to be environment friendly over a wider frequency vary.

From academia to the actual world

Within the early 2000s, researchers started to push CMUT know-how for medical ultrasound out of the lab and into business growth. Stanford College spun out a number of startups geared toward this market. And main medical ultrasound imaging firms equivalent to GE, Philips, Samsung, and Hitachi started growing CMUT know-how and testing CMUT-based probes.

Nevertheless it wasn’t till 2011 that CMUT commercialization actually started to make progress. That yr, a crew with semiconductor electronics expertise based Butterfly Community. The 2018 introduction of the IQ Probe was a transformative occasion. It was the primary handheld ultrasound probe that would picture the entire physique with a 2D imaging array and generate 3D picture knowledge. In regards to the dimension of a TV distant and solely barely heavier, the probe was initially priced at US $1,999—one-twentieth the price of a full-size, cart-carried machine.

Across the identical time, Hitachi in Tokyo and Kolo Medical in Suzhou, China (previously in San Jose, Calif.), commercialized CMUT-based probes to be used with standard ultrasound methods. However neither has the identical capabilities as Butterfly’s. For instance, the CMUT and electronics aren’t built-in on the identical silicon chip, which suggests the probes have 1D arrays reasonably than 2D. That limits the system’s potential to generate photos in 3D, which is important in superior diagnostics, equivalent to figuring out bladder quantity or taking a look at simultaneous orthogonal views of the guts.

Exo Imaging’s September 2023 launch of its handheld probe, the Iris, marked the business debut of PMUTs for medical ultrasound. Developed by a crew with expertise in semiconductor electronics and integration, the Iris is about the identical dimension and weight as Butterfly’s IQ Probe. Its $3,500 value is corresponding to Butterfly’s newest mannequin, the IQ+, priced at $2,999.

The ultrasound MEMS chips in these probes, at 2 by 3 cm, are a number of the largest silicon chips with mixed electromechanical and digital performance. The scale and complexity impose manufacturing challenges when it comes to the uniformity of the units and the yield.

These handheld units function at low energy, so the probe’s battery is light-weight, lasts for a number of hours of steady use whereas the machine is related to a cellphone or pill, and has a brief charging time. To make the output knowledge suitable with cellphones and tablets, the probe’s fundamental chip performs digitization and a few sign processing and encoding.

To supply 3D data, these handheld probes take a number of 2D slices of the anatomy after which use machine studying and AI to assemble the mandatory 3D knowledge. Constructed-in AI-based algorithms also can assist medical doctors and nurses exactly place needles in desired places, equivalent to in difficult vasculature or in different tissue for biopsies.

The AI developed for these probes is so good that it could be attainable for professionals untrained in ultrasound, equivalent to nurse midwives, to make use of the transportable probes to find out the gestational age of a fetus, with accuracy just like that of a skilled sonographer, in accordance with

a 2022 research in NEJM Proof. The AI-based options may additionally make the hand held probes helpful in emergency medication, in low-income settings, and for coaching medical college students.

Just the start for MEMS ultrasound

That is solely the start for miniaturized ultrasound. A number of of the world’s largest semiconductor foundries, together with TSMC and ST Microelectronics, now do MEMS ultrasound chip manufacturing on 300 and 200 mm wafers, respectively.

In actual fact, ST Microelectronics lately shaped a devoted “Lab-in-Fab” in Singapore for thin-film piezoelectric MEMS, to speed up the transition from proofs of idea to quantity manufacturing.

Philips Engineering Options provides CMUT fabrication for CMUT-on-CMOS integration, and Vermon in Excursions, France, provides business CMUT design and fabrication. Meaning startups and educational teams now have entry to the bottom applied sciences that may make a brand new stage of innovation attainable at a a lot decrease value than 10 years in the past.

With all this exercise, business analysts anticipate ultrasound MEMS chips to be built-in into many various medical units for imaging and sensing. As an example, Butterfly Community, in collaboration with

Forest Neurotech, is growing MEMS ultrasound for brain-computer interfacing and neuromodulation. Different functions embody long-term, low-power wearable units, equivalent to coronary heart, lung, and mind displays, and muscle-activity displays utilized in rehabilitation.

Within the subsequent 5 years, anticipate to see miniature passive medical implants with ultrasound MEMS chips, wherein energy and knowledge are remotely transferred utilizing ultrasound waves. Ultimately, these handheld ultrasound probes or wearable arrays might be used not solely to picture the anatomy but in addition to learn out important indicators like inside stress modifications attributable to tumor progress or deep-tissue oxygenation after surgical procedure. And ultrasound fingerprint-like sensors may in the future be used to measure blood circulate and coronary heart charge.

At some point, wearable or implantable variations might allow the technology of passive ultrasound photos whereas we sleep, eat, and go about our lives.

From Your Website Articles

Associated Articles Across the Internet