[ad_1]

Cement hides in plain sight—it’s used to construct all the pieces from roads and buildings to dams and basement flooring. However there’s a local weather menace lurking in these ubiquitous grey slabs. Cement manufacturing accounts for greater than 7% of world carbon dioxide emissions—greater than sectors like aviation, transport, or landfills.

People have been making cement, in a single kind or one other, for hundreds of years. Historic Romans used volcanic ash, crushed lime, and seawater to construct the aqueducts and iconic constructions just like the Pantheon. The fashionable model of hydraulic cement—the kind that hardens when combined with water and allowed to dry—dates again to the early nineteenth century. Derived from broadly accessible supplies, it’s low cost and simple to make. As we speak, cement is likely one of the most-used supplies on the planet, with about 4 billion metric tons produced yearly.

Industrial-scale cement is a multifaceted local weather conundrum. Making it’s vitality intensive: the within of a conventional cement kiln is hotter than lava in an erupting volcano. Reaching these temperatures sometimes requires burning fossil fuels like coal. There’s additionally a particular set of chemical reactions wanted to show crushed-up minerals into cement—and people reactions launch carbon dioxide, the commonest greenhouse gasoline within the environment.

One resolution to this local weather disaster could be coursing by way of the pipes at Chic Methods. Based by two MIT battery scientists, the startup is creating a wholly new technique to make cement. As a substitute of heating crushed-up rocks in lava-hot kilns, Chic’s know-how zaps them in water with electrical energy, kicking off chemical reactions that kind the primary components in its cement.

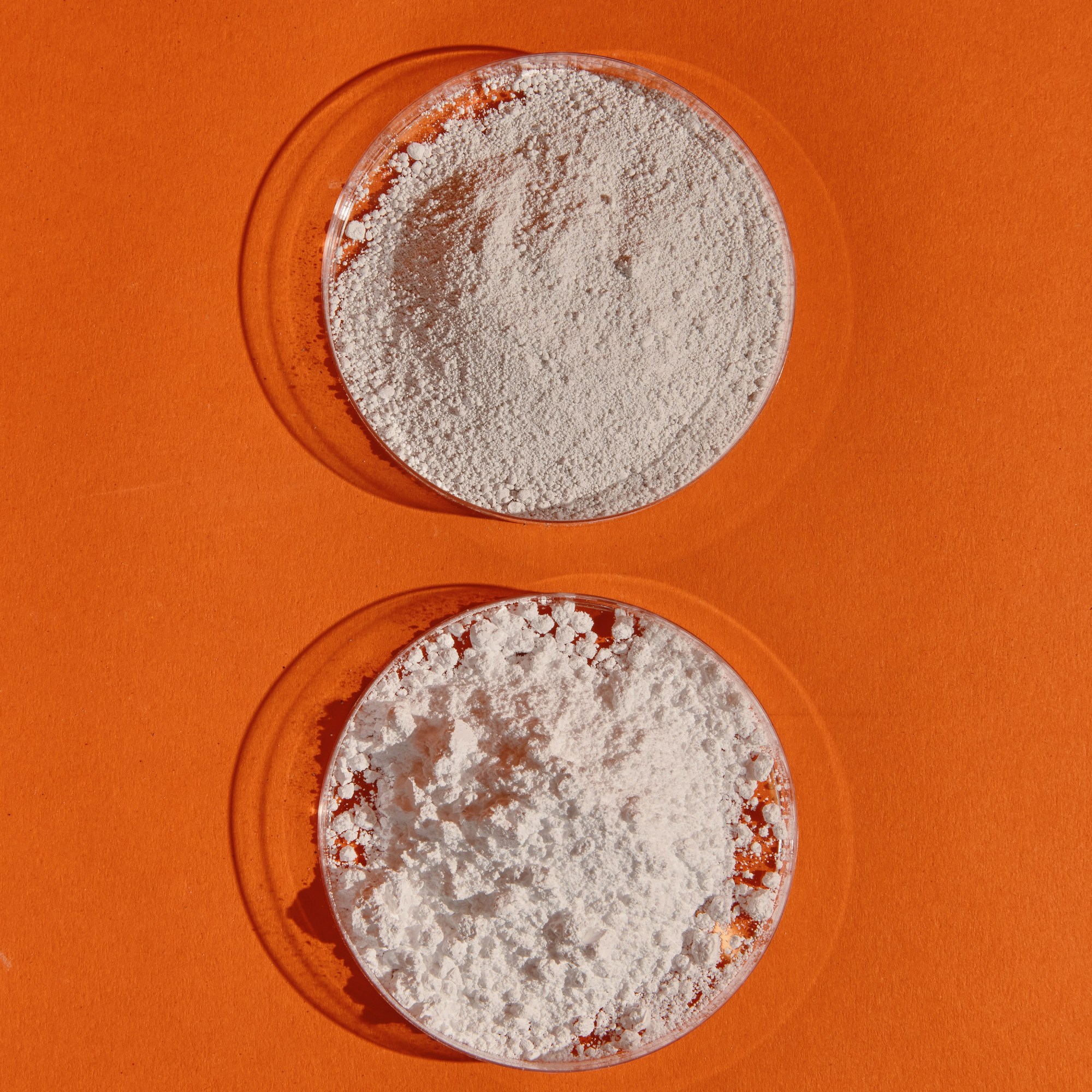

Chic silicates (high dish) and lime (backside dish) are the 2 foremost reactive parts for making Chic Cement.

Over the course of the previous a number of years, the startup has gone from making batches of cement that might match within the palm of your hand to beginning up a pilot facility that may produce round 100 tons annually. Whereas it’s nonetheless tiny in contrast with conventional cement vegetation, which might churn out one million tons or extra yearly, the pilot line represents the primary essential step to proving that electrochemistry can stand as much as the problem of manufacturing one of many world’s most essential constructing supplies.

By the top of the last decade, Chic plans to have a full-scale manufacturing facility up and operating that’s able to producing one million tons of fabric annually. However conventional large-scale cement vegetation can value over a billion {dollars} to construct and outfit. Competing with established trade gamers would require Chic to scale quick whereas elevating the extra funding it might want to help that progress. The top of 0% rates of interest makes such a activity more and more tough for any enterprise, however particularly for one producing a commodity like cement. And in a high-stakes, low-margin trade like building, Chic might want to persuade builders to make use of its materials within the first place.

The cement trade pumps 2.6 billion metric tons of carbon dioxide into the environment yearly. Cleansing that up would require addressing the 2 distinct sources of cement’s greenhouse-gas emissions: warmth and chemistry.

To make cement at the moment, a mix usually containing limestone, sand, and clay is floor up and baked in kilns at temperatures of as much as 1,500 °C (simply over 2,700 °F). The warmth kicks off reactions, remodeling limestone to lime and mixing that with silicon dioxide within the sand and clay. These reactions are advanced, however most often the essential ultimate product is a mix of some silicon, calcium, and oxygen compounds that enable the cement, after it’s combined with water (and sand and gravel are added), to harden into concrete, a sturdy constructing materials.

People use extra concrete, by weight, than some other materials besides water. Cement is the glue that holds that materials collectively, accounting for about 10% of its quantity.

Roughly 40% of the greenhouse-gas emissions related to cement manufacturing come from fossil fuels that generate the warmth required. It is a widespread drawback throughout heavy trade: fossil fuels have turn into ingrained in manufacturing processes due to their low value, says Rebecca Dell, head of the trade group on the nonprofit analysis group ClimateWorks. Nevertheless, lower-cost renewables are coming to the grid, opening the door for extra industrial sectors to modify to electrical energy.

It’s attainable to make use of electrical kilns to make cement, and a few main trade gamers, like Cemex, are working to pilot the know-how to chop emissions from warmth demand. These electrical kilns, if powered by renewable electrical energy, might present a possible pathway to reducing cement’s local weather impacts.

However that does nothing to treatment the opposite sources of emissions from cement manufacturing: the roughly 60% that come not from warmth however from the chemical reactions required to remodel the beginning supplies into the constructing materials.

Most cement begins with limestone, a sedimentary rock that incorporates calcium, oxygen, and carbon. In cement kilns, limestone is become lime via reactions that peel away carbon dioxide, which is normally launched into the environment. Limestone is about half carbon dioxide by mass, so these emissions can add up. Which means absolutely decarbonizing the cement trade may require a extra radical reinvention. That is the place Chic is available in.

“Cement doesn’t actually get the pizzazz that I believe it deserves,” says Leah Ellis, Chic’s cofounder and CEO. She speaks rapidly, as if operating quick on time, ideas pouring out and conveyed with a slight Canadian accent. As she explains the intricacies of cement chemistry, her eyes shine behind bubblegum-pink glasses.

Ellis didn’t all the time plan on moving into the constructing supplies enterprise. After rising up in Canada, she accomplished her graduate work beneath the famed battery pioneer Jeff Dahn. She then struck out for MIT to work with But-Ming Chiang, one other main determine in battery analysis and a serial entrepreneur. Chiang has based a number of vitality storage ventures, together with A123 Methods, 24M, and Type Vitality, and is now a cofounder of Chic Methods with Ellis.

When Ellis first arrived at MIT, it was Chiang who floated a special concept for her potential analysis there. She recollects him ushering her into his workplace and, to her shock, asking if she was tired of batteries. “And I assumed it was a trick query,” she says, “as a result of he’s clearly a well-known battery scientist.” However Chiang had an concept for making cement in a brand new method, utilizing a device from the battery-science device equipment: electrochemistry.

At full capability, the pilot line would take every week to make sufficient cement to provide a single concrete truck.

As a substitute of burning fossil fuels to warmth up cement kilns, Chiang prompt, there could be a technique to spark the mandatory chemical reactions to make cement utilizing electrical energy.

The staff later found {that a} machine known as an electrolyzer could be helpful in such a course of. Electrolyzers are gadgets that use electrical energy to kick off chemical reactions. They’re normally used to separate water into its parts, producing hydrogen and oxygen. However electrolyzers can work with different chemical reactions too, like producing acids and bases—the potential key to a brand new cement manufacturing course of.

By 2019, Ellis and her fellow researchers had found a technique with potential to satisfy Chiang’s preliminary concept. They discovered that an electrolyzer may very well be used to kind a pH gradient in a tank, with dissolved limestone on the acidic finish and hydrated lime on the opposite. That lime might then be mixed with reactive silica to kind the identical compounds fashioned by conventional cement.

After some extra technical growth and trade evaluation, the pair determined to spin out the analysis into an organization with Ellis on the helm. Chiang says, “It didn’t take very lengthy earlier than I acknowledged that there was each a beginning concept and in addition an individual to hold it.”

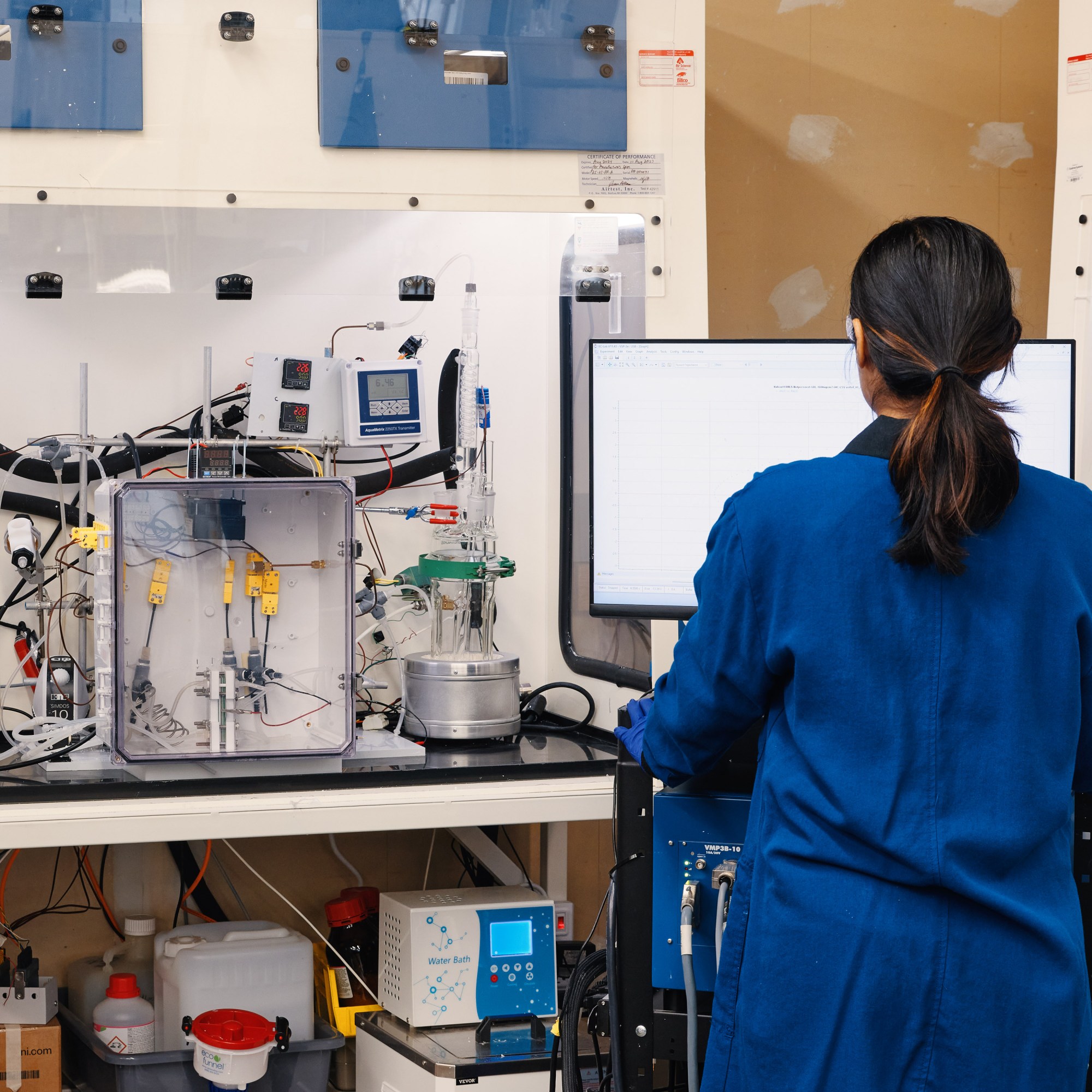

A Chic worker removes the corporate’s reactive silica product from its gear as a part of an R&D-scale manufacturing course of.

A Chic worker removes the corporate’s reactive silica product from its gear as a part of an R&D-scale manufacturing course of.

4 years later, Chic is operating a pilot manufacturing line. It’s a significant step up from the early days at MIT, the place Ellis and her lab mates would produce about sufficient materials to make a single die. The road began up in late 2022, says Mike Corbett, Chic’s director of engineering, and is 20 occasions bigger than something the corporate had run within the lab.

Inside a cavernous room on the startup’s headquarters, the stainless steel tanks lining the partitions of the pilot area are organized roughly from left to proper. Into tanks on one facet of the room go ground-up rocks, and out of these on the opposite comes hydrated lime, one of many foremost components in Chic’s cement.

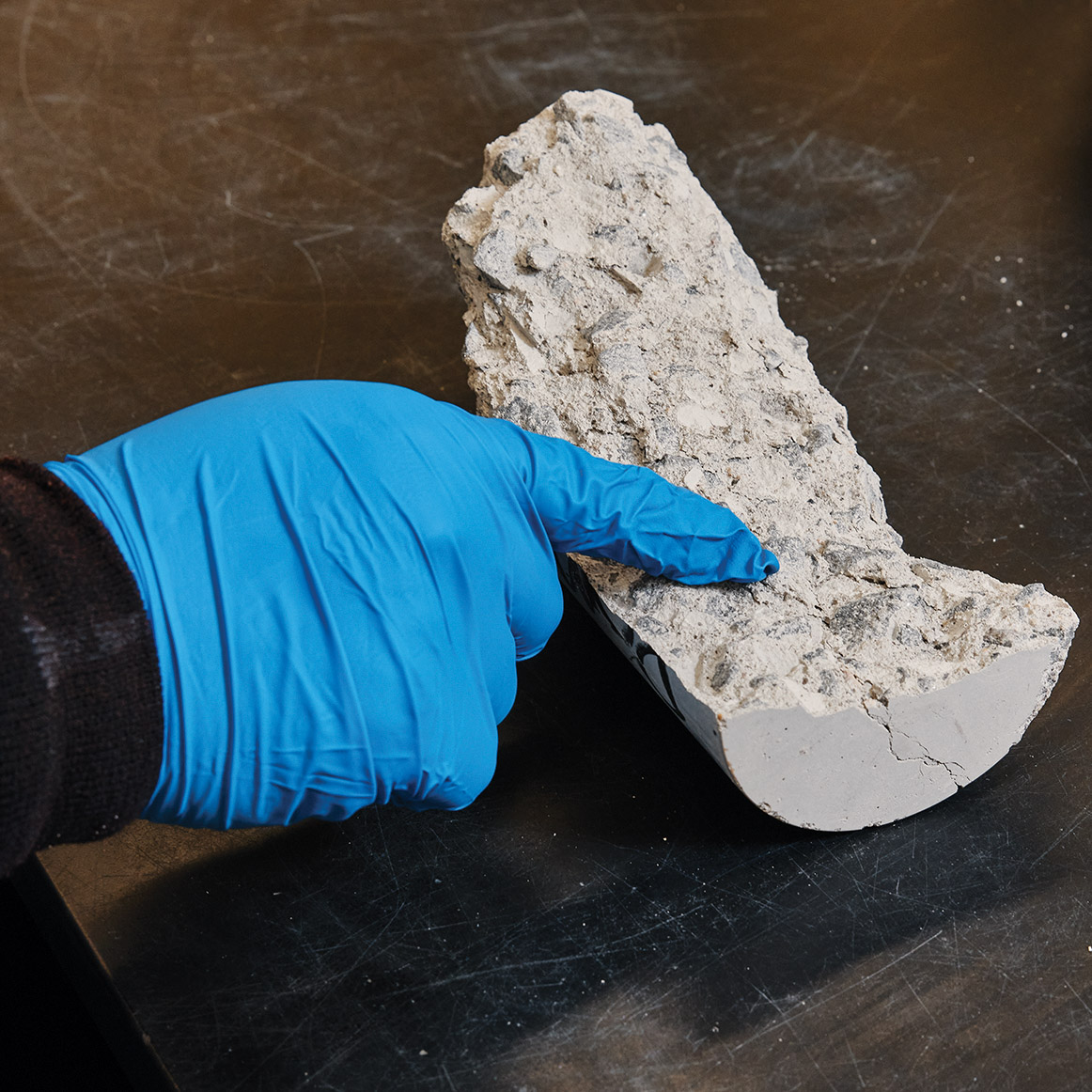

The outcomes of assorted experiments and trial runs sit close by, in five-gallon buckets stacked on steel racks. When Corbett and a colleague crack the lid on one, the hydrated lime inside is an unassuming white powder, chalky and barely clumped collectively like baking soda in a field that’s been left open for too lengthy.

It could be tough to make use of what’s in these buckets to construct something: at full capability, the pilot line would take a few week to make sufficient cement to provide a single concrete truck. And it takes three to 4 truckloads of cement to pour the inspiration for only one common single-family dwelling within the US.

As a substitute, the startup is making materials to ship to potential companions, operating assessments on cement blocks, and, crucially, serving to design the following services. These, which shall be considerably bigger, may very well be the ultimate step in proving that Chic’s course of can work within the cement trade.

Chic Methods isn’t the one participant making an attempt to inexperienced up the grey glue. Early efforts to chop emissions from cement have largely targeted on effectivity, says Radhika Lalit, the initiative director for trade on the Local weather Crucial Basis, who previously labored within the trade group on the Rocky Mountain Institute, a nonprofit analysis company. For instance, including fillers known as supplementary cementitious supplies, which might react with the lively components in cement, may help reduce down on complete emissions with out affecting the properties of the concrete.

This technique solely works as much as a sure level, Lalit factors out: after that, these fillers will start to degrade the energy and lifelong of cement.

There are different methods so as to add supplies to cement to chop local weather impacts. The Canadian firm CarbonCure Applied sciences, for instance, has developed know-how to inject carbon dioxide into cement mixtures. In accordance with CarbonCure, the gasoline can then react with the combination and mineralize, locking it away from the environment and including to the fabric’s energy. CarbonCure is working with carbon removing firms like Heirloom Carbon Applied sciences to exhibit the opportunity of utilizing concrete for long-term carbon dioxide storage.

However strategies like reducing down the whole materials used or including in fillers are restricted in how a lot they’ll reduce emissions: it’s not attainable to make limitless effectivity tweaks to get to zero. So many established gamers within the cement world wish to add carbon seize and sequestration vegetation to present services, Lalit says. By snaring carbon dioxide from plant exhaust earlier than it may be launched into the environment, this add-on helps lively services reduce their emissions in order that making the trade cleaner doesn’t require changing them solely.

Including carbon seize know-how to present infrastructure might imply an extended lifetime for typical gear, a significant profit for not too long ago constructed vegetation which might be usually designed to run for 30 to 50 years. However carbon seize remains to be largely unproven in heavy trade: present strategies usually aren’t capable of seize all emissions, and the few present large-scale items have confronted delays, Lalit says.

To be on observe for net-zero objectives, the cement trade would wish so as to add carbon seize services to between 33 and 45 present cement vegetation by 2030, in response to RMI. The primary such industrial-scale facility at a cement plant is scheduled to come back on-line this yr.

This may very well be costly: a carbon seize system might value as a lot as $120 per metric ton of carbon dioxide eliminated, which Ellis says would roughly double the ultimate value of cement at present costs.

The price is one cause Chic and plenty of different startups are eschewing carbon seize and aiming to chop cement’s carbon footprint utilizing extra radical formulation.

One of many different best-funded cement startups is Brimstone, a California-based group with what it calls a carbon-negative course of for making cement. Because of this the product finally ends up pulling extra carbon dioxide out of the environment than it emits, says Cody Finke, Brimstone’s CEO.

engaged on designing its subsequent services, which can have even higher capability.

This works in two main methods. First, slightly than limestone, Brimstone makes use of different minerals known as silicates that don’t comprise carbon dioxide, so there aren’t any course of emissions from the corporate’s cement, says Finke. As well as, a waste product of the silicates is a magnesium-containing materials that acts like a sponge, absorbing carbon dioxide from the air and mineralizing it.

There are nonetheless emissions related to making Brimstone’s cement, largely associated to the warmth required. However they are often successfully canceled out with the mineral course of, Finke explains, particularly because the firm plans to make use of electrical kilns. If these are powered by electrical energy from the common US energy grid, the startup claims, its materials would wind up eradicating extra carbon dioxide than it produces—about 130 kilograms extra per ton of cement.

The rationale Brimstone is sticking to this high-temperature course of, regardless of its related vitality wants and emissions, is that it’s producing a cement with a chemical formulation that dominates the trade at the moment. Portland cement, which has been round because the early 1800s, is probably going what you consider once you consider cement. It’s identified for producing predictable and powerful concrete. Nevertheless, there’s a catch: making it necessitates ultra-high warmth, as a result of a key ingredient of the cement—alite—can solely kind at temperatures over 1,250 °C.

“A cement startup might be one of the vital tough ones you’ll be able to think about. Not solely is it technically tough, nevertheless it’s very capital intensive … And it’s not horny.”

Leah Ellis, Chic’s cofounder and CEO

Initially, Chic deliberate to make Portland cement as effectively. “For one thing as low-cost as cement, we thought you’d want to provide what the market is used to utilizing,” Chiang says. However the temperature necessities pushed Chic to rethink because it started making its product at bigger scales: “There was this 200-year-old invention that we had been inventing round.”

So the staff went searching and found that there are different pathways to the chemical bonds that give concrete made with Portland cement its energy. Chic’s materials takes one among these various routes: slightly than alite, it makes use of lime and reactive silicates to react with water to kind the ultimate materials.

The selection of cement chemistry may look like a minor quibble. However in a high-stakes trade like building, it may very well be a key deciding issue during which startups win giant contracts and partnerships, and which fizzle out. “Persons are, I believe, rightfully skeptical of a brand new cement,” Ellis says, earlier than stopping herself: “Properly, it’s and it isn’t a brand new cement.”

Ellis maintains that Chic’s materials is as sturdy and sturdy as Portland cement, if no more so. However there’s an opportunity that builders shall be hesitant, no less than initially, to maneuver away from the fabric they already know, says Local weather Crucial’s Lalit.

One of many main challenges forward for Chic is making its materials on the large scales required for giant constructing tasks. Trendy cement services can sometimes produce over one million tons of cement annually, whereas Chic’s pilot could make about 100 tons per yr. It’s mainly “a cement plant for ants,” Ellis says.

Chic has its sights set on scaling, and rapidly. The following stage for the startup is an illustration business facility producing tens of hundreds of tons of fabric annually, which ought to come on-line in early 2026. “That’s the dimensions the place you’re now not invisible to the cement world,” Ellis says.

After that will come a full-scale business plant able to the million-ton annual manufacturing capability that’s typical of the trade. The corporate remains to be understanding the place to construct that, although the hope is to get it operating round 2028.

Chic’s founding duo isn’t naïve in regards to the challenges forward. “A cement startup might be one of the vital tough ones you’ll be able to think about,” Ellis says. “Not solely is it technically tough, nevertheless it’s very capital intensive. It’s large. And it’s not horny … everyone makes use of and owns cement, however they don’t see it.”

However fixing this invisible drawback might rework the world round us. Cement scaffolds our society, and efforts to alter it—regardless of the great challenges they face—are crucial to cleansing up the way forward for building.

[ad_2]